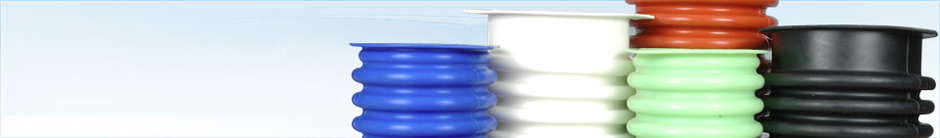

Corrugated Shaker & Tubing Boots

Our accordion style corrugated boots are designed to be in conjunction with gyratory and vibratory equipment. They are molded in a variety of high quality compounds to suit your specific application requirements. We have included a chemical resistance chart to assist you in choosing the compound that best fits your needs.

- Style “A” boots are 10-3/4” long. They are molded in 4”, 6”, 8” & 10” diameters. They are designed to stretch-fit over single beaded rings, engaging a ¼” bead for quick installation. Fits Rotex-style screeners

- Style “B” boots are 12” long. They are molded in 6” & 8” diameters. They are designed to fits over a straight pipe or flange. They are most often attached with hose clamps. This style is commonly used on circular vibratory separators.

Available Compounds

- Black Natural

- White Natural - Food Grade

Natural rubber has excellent abrasion resistance and tear strength - Black Neoprene

- White Neoprene - Food Grade

Neoprene is highly resistant to fats, oils, weather & ozone - Red Silicone

- Translucent Silicone - Food Grade

Silicone does well in applications with higher temperatures, weather, oxidation & ozone. - Black EPDM

- White EPDM

Contact us today to talk to a representative from Custom Advanced

or call us at (888) 810-2666.